THERMOPAC EXCEL - TPD

The assurance of the highest efficiency in its class

Options available

- Horizontal orientation

- Separate deaerators and common expansion tank for

multiple unit installations

- High temperature options up to 380 C

- Complete heater house and accessories on turnkey basis

Product highlights

- Specially designed and patented air preheater

- Combination of cross and parallel flow arrangement of air and flue gas circuit

- Modular design of the unit ensures quick assembly and compact layout

- Designed and verified by modern tools like CFD and FEA

Product offering

- Fuel – Light Oil,Heavy Oil & Gas

- Capacity – 1 to 2.5 million kcal/hr

- Operating Temperature – 280 °C

Air Pre-heater

Thermopac Excel TPD comes with a noncorrosive air pre-heater with a hybrid cross and counter flow design that has been validated with extensive CFD analysis.

- Air is introduced in the intermediate flue gas zone which maximizes heat recovery and reduces stack temperature

- Diverter damper in flue gas line facilitates online cleaning of the APH and use of only one module while the other is under cleaning

- Modular APH helps to maintain efficiency even under part load conditions

- No risk of dew point corrosion as the configuration ensures optimum metal temperatures

THERMOPAC – TPCM

Product offering

- Fuel – Heavy Oil, Natural Gas & LPG

- Capacity – 0.1 to 0.2 million kcal/hr

- Operating temperature – 280 °C

Product highlights

- Apply designed for mid size temperature and very low

heating requirements

- Imported monobloc burner

- Ideal for the packaging, colour printing, pharmaceutical

and leather industries

- Compact and reliable

Technical specifications – TPCM series

Engineered for reliability

- Designed according to DIN 4754, to ensure longer life of heater and thermic fluid

- Adequate furnace volume and heat transfer surface ensure higher thermal efficiency

- Pre-wired and pre-assembled for quick and easy installation

Compact Deaeratorcum- Expansion Tank

- Requiring less space, it comes with a buffer vessel to prevent cooling of hot oil coming from the process

- The tangential thermic fluid entry in the deaerator ensures optimal deaeration

Manufacturing excellence

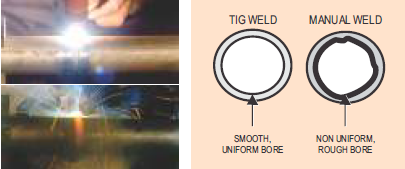

Fully automated tube to tube TIG Welding Machine enables smooth uniform bore

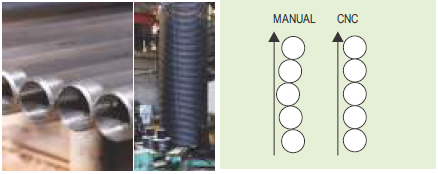

CNC coil winding machine ensures proper alignment, avoiding possibility of hot spots

Typical P & I diagram for thermic fluid heating system

Technical specifications – TPDi series

Technical specifications – TPD series